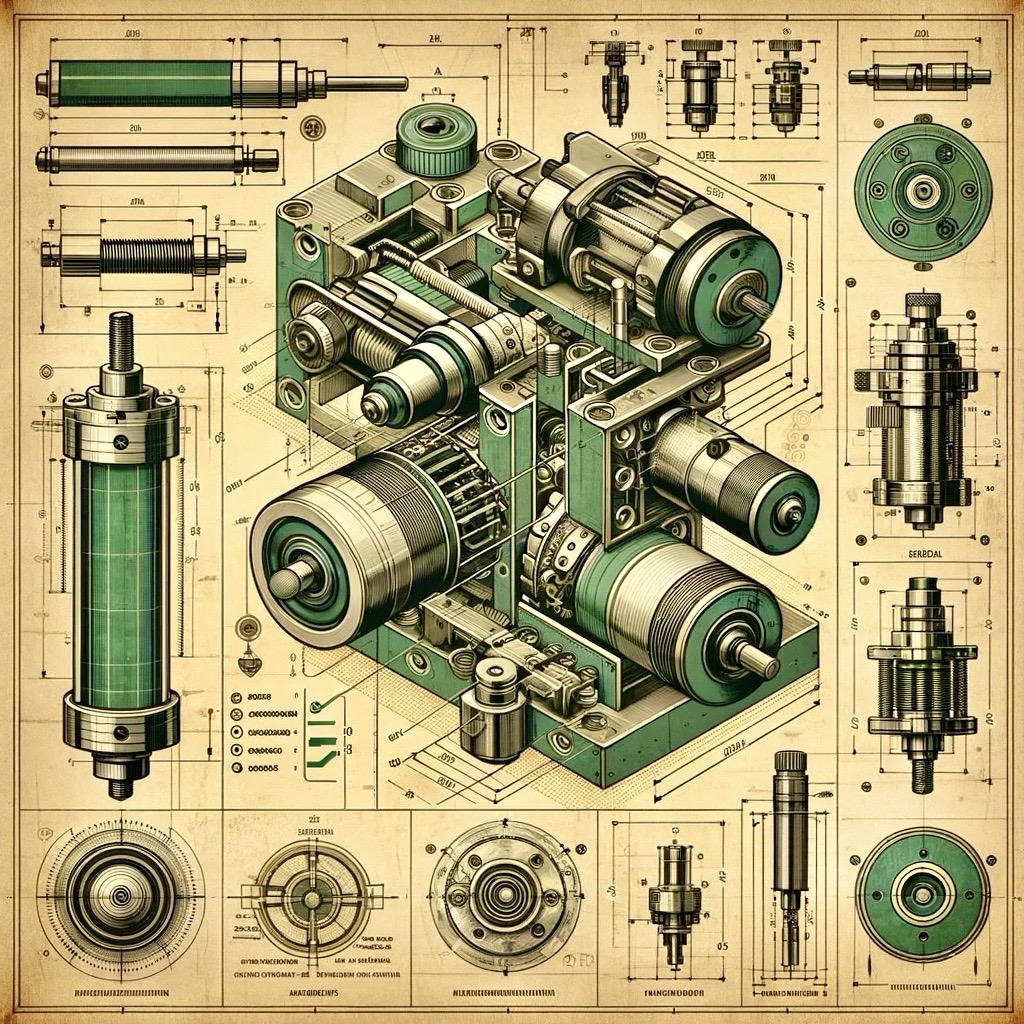

Introducing Actuators

Actuators are devices that take signals from a controller and perform physical actions, such as movement or controlling a mechanism. This tutorial will introduce various types of actuators, explain how to interface them with microcontrollers, and provide hands-on project ideas to help you get started.

Common Types of Actuators

1. Motors

Motors are among the most commonly used actuators in various applications, converting electrical energy into mechanical motion. They can be grouped based on their operating principles, each suited to specific tasks and environments:

Direct Current (DC) Motors

DC motors are powered by a direct voltage source, making them ideal for applications requiring speed control and quick response. They are commonly used in robotics, small appliances, and automotive applications. Types of DC motors include:

- Brushed DC Motors: Simple and cost-effective, but require regular maintenance due to brush wear.

- Brushless DC Motors (BLDC): Highly efficient and durable, with no brushes to wear out. Ideal for drones, electric vehicles, and precision instruments.

Alternating Current (AC) Motors

AC motors are powered by alternating current and are widely used in industrial and household applications. They are known for their durability and efficiency. Types of AC motors include:

- Induction Motors: Rugged and reliable, commonly used in fans, pumps, and conveyors.

- Synchronous Motors: Operate at a constant speed, often used in clocks and timers.

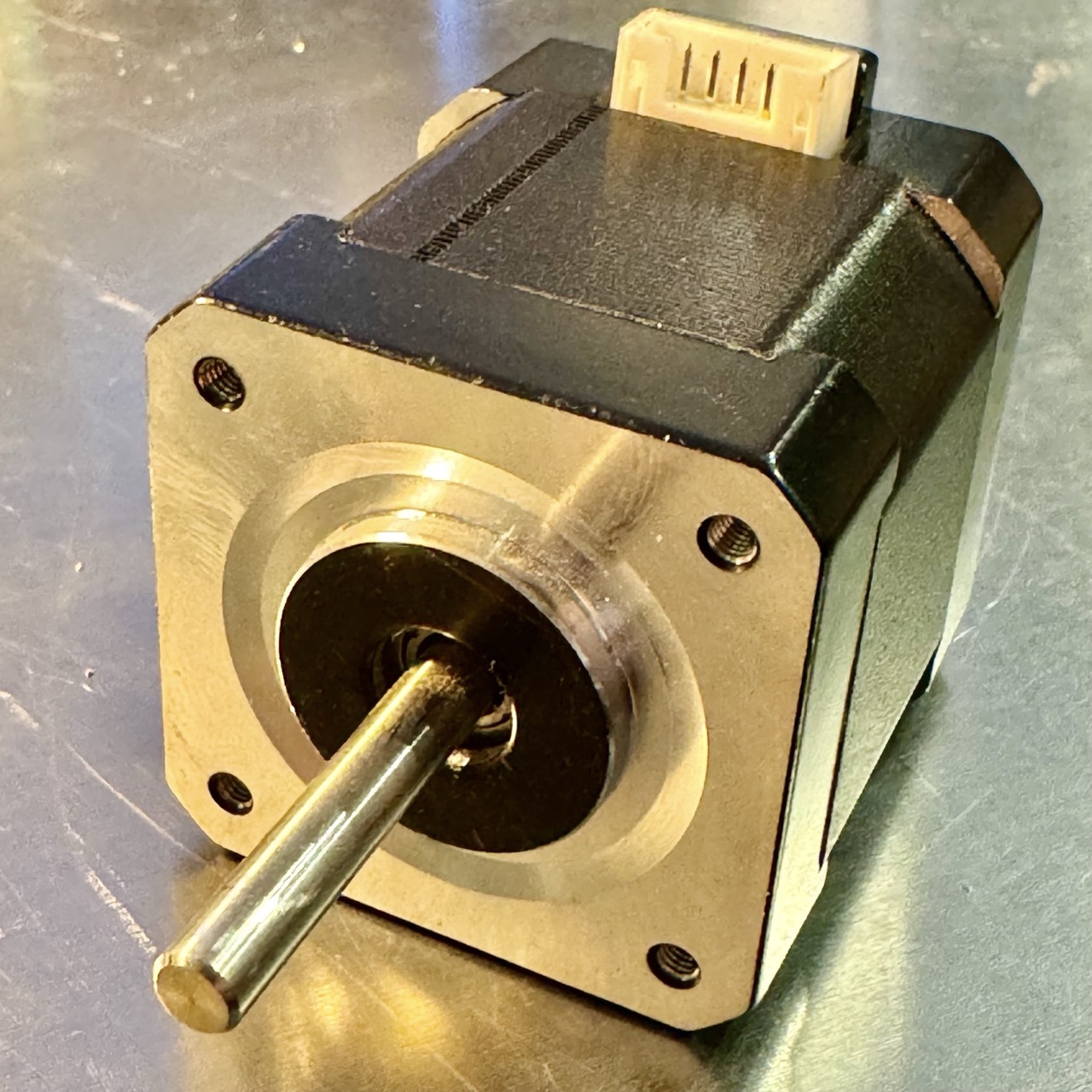

Stepper Motors

Stepper motors are precision actuators that move in discrete steps, allowing for precise control of position and speed. They are commonly used in CNC machines, 3D printers, and robotics. Types of stepper motors include:

- Unipolar Stepper Motors: Simplified wiring, suitable for low-torque applications.

- Bipolar Stepper Motors: Provide higher torque and efficiency, requiring more complex drive circuitry.

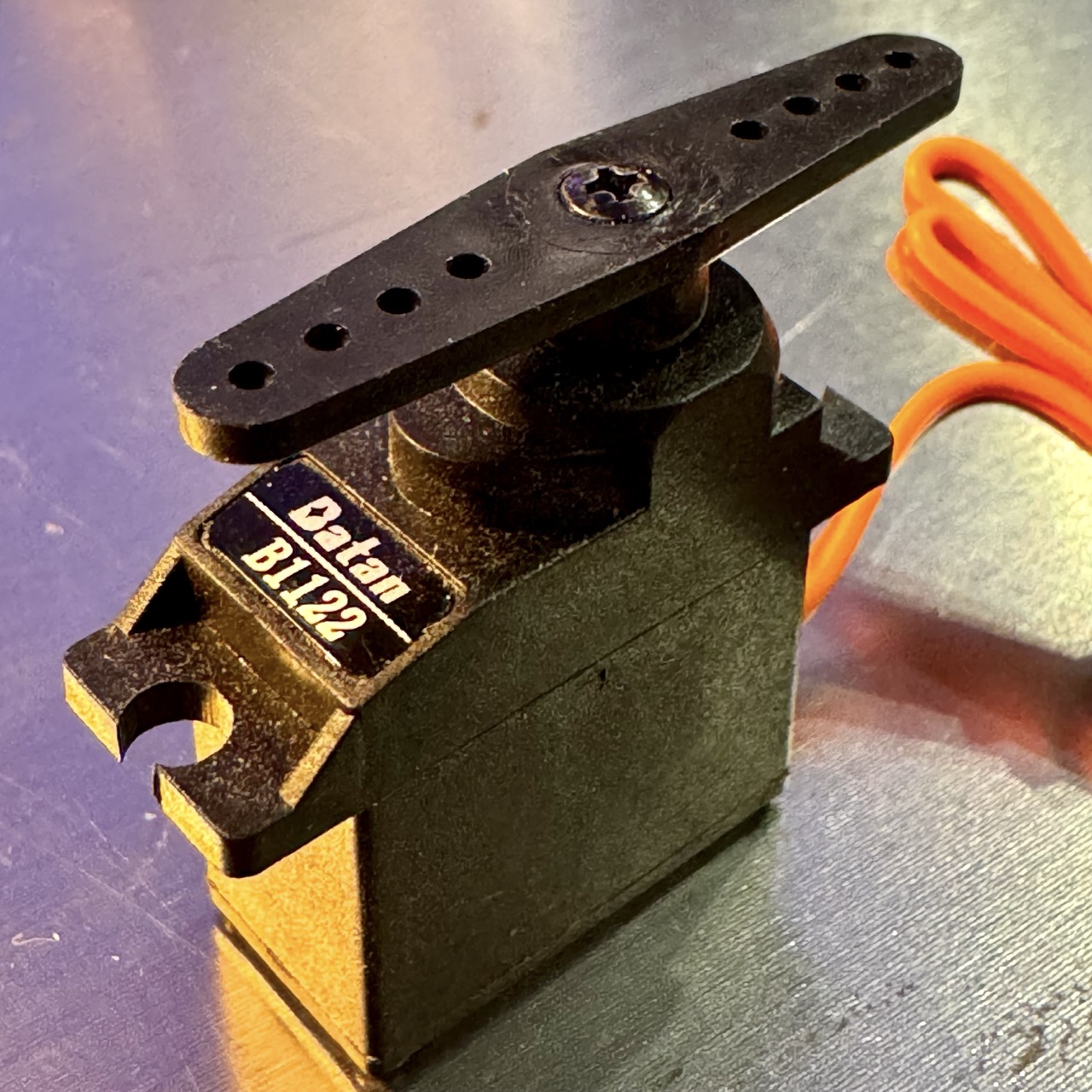

Servo Motors

Servo motors combine a motor with position feedback and control circuitry, allowing precise control of position, speed, and acceleration. They are widely used in robotics, automation, and camera systems.

Specialty Motors

Some motors are designed for specific use cases:

- Linear Motors: Provide linear motion directly, used in maglev trains and conveyor systems.

- Torque Motors: Deliver high torque at low speeds, ideal for industrial and robotics applications.

- Coreless Motors: Lightweight and efficient, often used in drones and medical devices.

Each type of motor offers unique advantages, and selecting the right motor depends on the application's requirements for speed, torque, precision, and efficiency.

2. Linear Actuators

Linear actuators create linear motion, commonly used in automation, robotics, and industrial machinery.

3. Piezoelectric Actuators

Piezoelectric actuators use the piezoelectric effect to create small, precise movements, commonly used in optics, precision tools, and medical devices.

4. Thermal and Magnetic Actuators

These actuators use heat or magnetic fields to create motion, typically for specialized or niche applications.

Learn About Motor Drivers

Motor drivers are essential for efficient and precise operation of actuators. They interface between microcontrollers and actuators, providing power and control signals. Explore tutorials on motor drivers for different motor types:

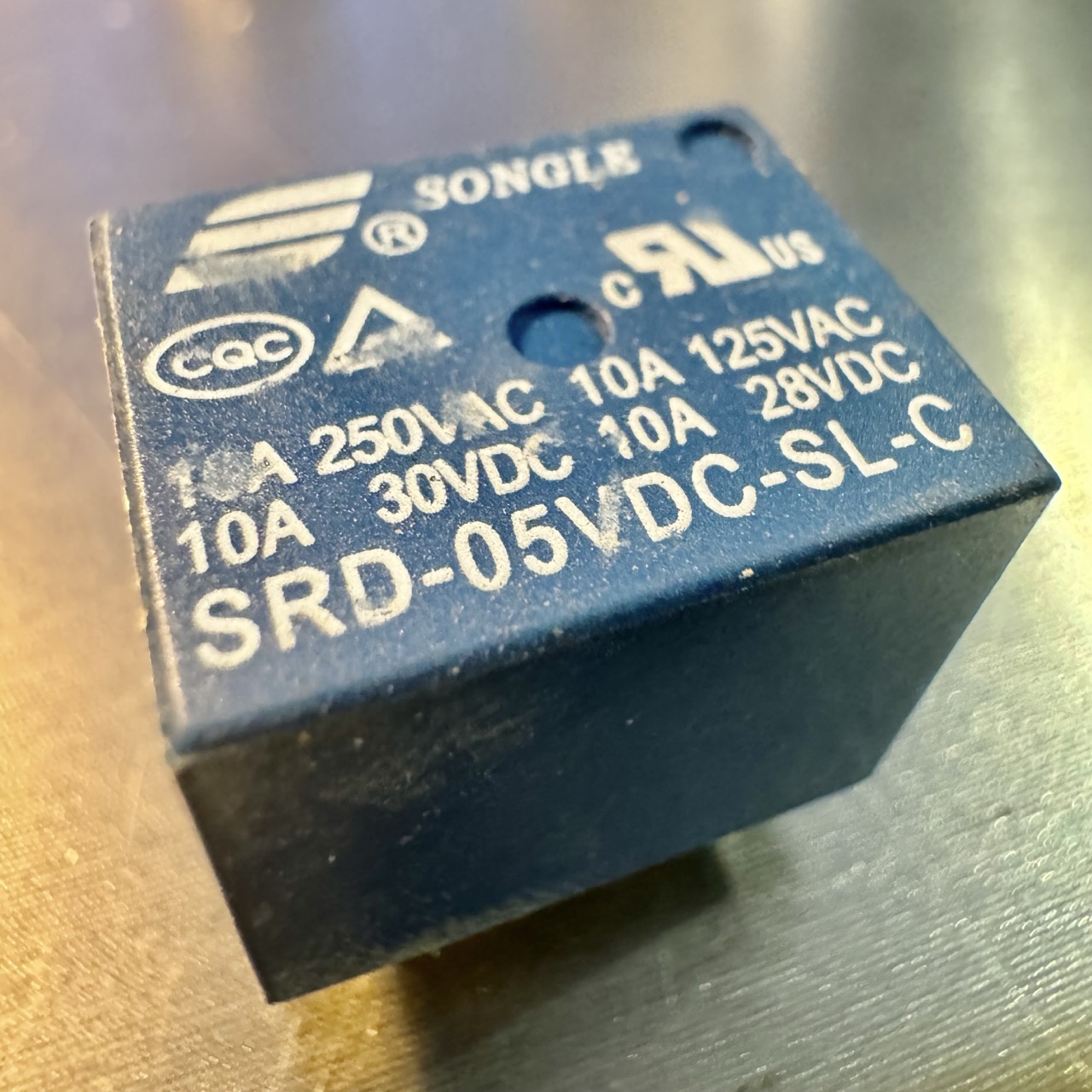

5. Relays

Relays are electrically operated switches that control circuits, allowing low-power signals to switch high-power loads. They provide isolation and timing control across various applications.

Electromechanical Relay

Uses an electromagnet to move contacts, commonly used in automotive and industrial systems for switching high-voltage circuits with low-voltage control signals.

Solid State Relay (SSR)

Employs semiconductors to switch without moving parts, providing fast, durable switching in industrial and high-frequency applications.

Time Delay Relay

Delays switching action after control signal activation, ideal for applications like lighting and process control systems where timing is essential.

Reed Relay

Compact relay using magnetic contacts in a reed switch, used in small devices like alarms and sensors where space is limited.

Polarized Relay

Relies on a permanent magnet for directional control, suitable for systems needing precise switching, like telephone circuits.

Latching Relay

Holds its state after activation, making it energy-efficient for memory storage and applications where position retention is required.

Thermal Relay

Operates using a bimetallic strip that bends under heat, commonly used in motor protection and overheating prevention systems.

Mercury Relay

Fast-switching relay with low resistance, using mercury in a sealed environment, suitable for high-precision applications.

High-Sensitive Relay

Functions with low control voltages, typically found in low-power circuits, alarms, and sensors.

Miniature Relay

Small relay for space-constrained applications, commonly found in consumer electronics and automotive systems.

How to Interface Actuators with MCUs

Microcontrollers (MCUs) like the Arduino can control actuators through digital and PWM signals. Here's a simple project to control a servo motor with an Arduino:

Practical Project: Controlling a Servo Motor with Arduino

Components Needed:

- Arduino Uno

- Servo Motor

- 10k Potentiometer

- Jumper Wires

Code:

#include

Servo myServo; // Create a Servo object

void setup() {

myServo.attach(9); // Attach servo to pin 9

}

void loop() {

for (int angle = 0; angle <= 180; angle++) {

myServo.write(angle); // Move servo to current angle

delay(15); // Short delay for smooth movement

}

for (int angle = 180; angle >= 0; angle--) {

myServo.write(angle);

delay(15);

}

}

Wiring:

Connect the servo motor as follows:

- Servo Motor:

- Red wire to 5V on the Arduino

- Black wire to GND on the Arduino

- Signal wire to digital pin 9 on the Arduino

Conclusion:

With this setup, your Arduino will control the servo motor, moving it smoothly between 0 and 180 degrees in a continuous loop.

Further Experiments

- Try using a DC motor with an H-bridge motor driver to control its direction and speed.

- Experiment with a stepper motor to achieve precise rotational control for projects like robotic arms or positioning systems.

- Control a DC Motor with Arduino

- PWM Speed Control of a DC Motor

- Bidirectional Control of a DC Motor with H-Bridge

- Stepper Motor Control with Arduino

- Precise Positioning with Stepper Motors

- Servo Motor Control with Arduino

- Sweep Motion Control of Servo Motors

- Controlling a Linear Actuator with Arduino

- Interfacing Piezoelectric Actuators

- Magnetic Actuator Experiment

- Controlling Thermal Actuators

- Relays as Actuators for Light Control

- Building a Relay-based Switch Circuit

- Create a Latching Relay Circuit

- Electromechanical Relay Demonstration

- Solid State Relay Experiment

- Control LEDs with a Relay

- DIY Robotic Arm with Servo Motors

- Use a Motor Driver to Control a DC Motor

- Control a 12V DC Fan

- Experiment with Solenoids

- Create an Electromagnet Switch

- Control a Vibration Motor

- Use Piezo Buzzers for Sound Output

- Interface a Heating Element as an Actuator

- DIY Electric Door Lock Using a Solenoid

- Control a Water Pump with Arduino

- PWM-based Speed Control of Fans

- Build a Simple Elevator with Motors

- Use Actuators to Simulate a Robotic Gripper

- Control a Conveyor Belt System

- Experiment with Pneumatic Actuators

- Control a Hydraulics-based Actuator

- Use Thermal Relays in Safety Systems

- Automate a Gate with a Linear Actuator

- Create a DIY Solar Tracker Using Motors

- Build a Self-balancing Robot

- Interfacing Smart Servo Motors

- Temperature-based Fan Control System

- Create a Windshield Wiper Simulation

- Use Actuators for Door Automation

- Control a Peristaltic Pump

- Build a Sliding Drawer System

- Servo-Controlled Camera Gimbal

- Use Relays in a Smart Lighting System

- Magnetic Field Experiment with Actuators

- Design a Programmable Car Wiper

- Control RGB LEDs with Relays

- Create a Motorized Window Blind

- DIY Robotic Claw Using Servo Motors

- Experiment with High-Sensitivity Relays

- Design a Mini Elevator System

- Control a DC Motor Using Bluetooth

- Create an Automated Curtain System

- Stepper Motor Control for Precision Tools

- Build a Water Level Controller

- Interface an Actuator with Raspberry Pi

- Control a Gear Motor

- Experiment with Servo Speed Control

- Design a Car Steering Simulation

- Use Micro Servos for Small Applications

- Build a Microcontroller-controlled Vent

- Piezoelectric Actuator Vibration Control

- DIY Conveyor System Using Motors

- Create a Remote-controlled Gate System

- Use Actuators in a Robotic Hand

- Experiment with Electromechanical Relays

- Build a Smart Fan Speed Controller

- Create a Robot Arm with Servo Motors

- Control an LED Strip with a Relay

- DIY Smart Window Closer

- Use Relays for HVAC Control

- Build a Line-following Robot

- Experiment with 3D Printer Motors

- Create a Servo-controlled Traffic Light

- Automated Irrigation System

- Build a DC Motor Speed Tester

- Experiment with Robotic Wheel Drives

- Control Lights in Series Using Relays

- DIY Solar Panel Actuator

- Test a Motorized Trolley

- Experiment with Pneumatic Cylinder Control

- Build a Remote-controlled Fan

- Design a Programmable LED System

- Piezo-based Precision Control

- Control Miniature Motors with MCU

- Build an Obstacle-avoiding Robot

- Create a Water Dispensing System

- Control Actuators with Voice Commands

- Experiment with Remote Servo Control

- Design a DIY Actuator-based Door Lock

- Create a Programmable Light Switch

- Stepper Motor Rotation Control

- Design a Smart Irrigation Valve

- Experiment with Solar-powered Motors

- DIY Rolling Gate System

- Use Actuators in Wind Turbine Models

- Build an Automated Water Dispenser

- Experiment with High Torque Motors

- Create an Automated Greenhouse